How-to Identify Woven Chair Seats

You’ve probably run across several examples of woven chair seat patterns before but didn’t recognize the differences in designs and weaving techniques.

You might have seen woven chair seat patterns at your parents or grandparents’ houses, antique shops, flea markets, home furniture stores or online.

But did you know each of the different patterns and materials all has special names and they are not all called, “caning”?

Through this article complete with photos, you will be able to identify at least seven of the most popular and common types of chair seat weaving.

Seven Most Common Types of Chair Seatweaving Patterns

- Traditional Hole-to-Hole, Hand or Lace Chair Caning

- Pressed Cane, Machine Woven or Cane Webbing

- Wide Binding Cane or Porch Cane

- Natural Hand-twisted Bulrush & Cattail Leaf Rush

- Man-made Paper Fibre Rush

- Ash, Oak, Hickory, Rattan Reed Splints or Paper Splint

- Danish Modern Cord or Danish Modern Cane

- Shaker Cotton or Wool Tape

Most people lump all chair seat patterns and weaving techniques together and call them either “wicker” or “caning,” but neither word is really accurate.

The words wicker and caning don’t really identify the chair seat pattern and material at all, those terms simply refer to a woven piece of furniture or a specific type of woven seat.

Technically speaking, each woven chair seat goes by a particular name to identify it. Most names are derived from the actual weaving process itself or the materials used in creating the woven chair seat.

All woven seats are done completely by hand, there hasn’t been a machine invented to do all the weaving or application of the materials entirely. In this article, we will highlight the seven most well-known types of chair seat weaving.

HOLE-TO-HOLE TRADITIONAL STRAND CANING

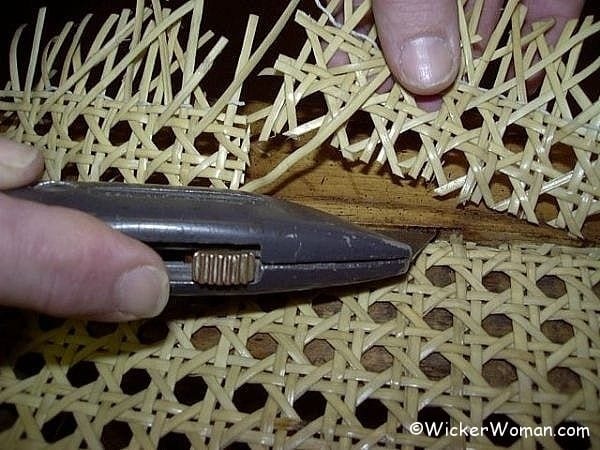

Traditional hole-to-hole chair caning is a well-known seatweaving technique, woven by hand one strand at a time, laced through a series of drilled holes in the frame, using a material called “cane.”

This cane weaving material comes from the rattan palm and is imported from places like Malaysia, Asia, China, Africa and the Philippines to the USA.

Chair cane is the skin or the bark of the rattan palm which is under a thorny surface. Cane has a natural glossy side that is the right-side-up or visible side, with a very porous wrong side.

There are holes drilled through the frame of the chair on the outer perimeter that the strands of cane are woven or “laced” through. By the way, these drilled holes are the “holes” you will count when asking an expert to repair your chair seat.

Generally speaking, the cost of hole-to-hole cane seating repair is based on the number of drilled holes in the frame, times the dollar amount the expert charges.

Traditional hole-to-hole or strand hand caning is woven with a variety of gauges of cane, all determined by the size of the holes drilled into the chair frame and the distance between holes.

The traditional hand-caning weave used is a very distinctive and common series of octagon holes in the pattern when completed.

And although there are a number of various cane patterns and designs, this seven-step method has proved to be the most durable and longest-lasting of the various hole or lace caning patterns over several centuries.

The average lifespan of this chair seat pattern is 25 years, with good care and maintenance.

SPLINE CANE, PRESSED CANING or CANE WEBBING

Spline cane, machine woven cane or pressed cane webbing is a method of weaving cane on a mechanized loom which creates a sort of “fabric” of cane.

The chair has a routed out groove on the perimeter of the top side of the seat frame to accommodate the cane and it’s held in place with the addition of water-soluble glue.

This “sheet” of “machine woven cane” “webbing” is “pressed” into the groove and held in place with glue and spline, hence the several different terminologies for the same chair seat weaving technique and material.

Loom-woven, sheet cane or machine-woven cane webbing was invented in the 1870s, so has been around for a very long time and is very popular even now.

It’s quick and easy to apply (especially for manufacturing companies) and doesn’t take the long man-hours to complete the weaving steps as does the traditional hole cane or hand caning technique.

There are a wide variety of pre-woven patterns to choose from now, too. But in the Victorian times of the 1800s and early 1900s, the preferred design was the close-woven cane sheeting.

Close-woven sheet cane was used especially on the fancy heavily embellished wicker furniture of the era.

The cane sheeting material was closely woven without any holes, so the caning did not detract from the fancy curlicues and embellishments on the backs and arms of the woven wicker furniture from the Victorian era.

PORCH CANE, WIDE BINDING CANE, or BINDERS CANE

Porch caning or wide-binding cane seats are woven around the rungs of the seat or backs of chairs, settees, and rockers.

The pattern may be the same on the bottom as on the top, but not always. Patterns are frequently changed to a less fancy weave on the bottom than the fancy, more intricate pattern displayed on the top.

Wide binding cane is used for this twill or diamond pattern caning, usually in the 6MM wide cane gauge, which is then woven in a variety of patterns.

The twill or herringbone pattern is simple and easy for most chair caners to master. But there are several other designs such as the basketweave, Carolina weave, fan, diamond weave and other variations to choose from.

HAND-TWISTED CATTAIL LEAF RUSH AND BULRUSH

The seatweaving process using bulrushes and cattails has been around since the earliest of recorded times, documentation exists that it was used during the times of the Pharaohs in Egypt.

Rush weaving was also extremely popular in Europe during the early 1400s and later here in the United States.

Bulrush and especially cattails grew prolifically and were readily available for everyone to use, from the poorest farmer to the chair seat weavers of the High Courts.

Natural cattail leaf rush or bulrush (which is similar but slightly different material than the cattail leaves), is typically woven around the four-seat rails (dowels), of a post and rail chair frame.

Here’s what the natural rush weaving process looks like, using wet or mellowed hand-twisted bulrush stems.

The twisted stems are woven from the outside of the frame to the center and create four envelope flap-shaped triangles that meet in the center.

Although the seat is a variegated green-tan color, that will change to a totally tan or honey color over the years as it dries and cures.

Completed natural hand-twisted bulrush chair seat. See those triangular-shaped or envelope-flap-shaped sections that meet in the center?

Each twisted strand varies a bit in diameter since this is a hand-twisted product, made with several cattail leaves or bulrush stems of different widths and lengths. This is a normal variation in all hand-woven rush seats.

For those of you that can’t master the hand-twisted natural rush technique, pre-twisted natural rush is also available from the supply companies listed on the Cane and Basket Supplies Directory™ here on WickerWoman.com.

Pre-twisted rush is made from seagrass strands and sold as “reel rush” or “real rush,” packaged and sold in one or two-pound coils, 10-pound coil or 35-pound reels.

MAN-MADE PAPER FIBRE RUSH or PAPER WICKER

Paper fibre (spelling to denote man-made product versus natural) rush can be identified by its barber-pole or peppermint stick twist and each strand is exactly the same size in diameter.

The man-made paper material used in this seatweaving process was invented in 1904 and was made to resemble the rattan reed that had been used in Victorian wicker furniture.

Paper rush is actually made from twisted thin sheets of paper that have been glued and sized to stay twisted.

This rope-like material resembles the strands of natural cattail leaf rush or bulrush as well as round, rattan reed.

Paper twist, rope, or paper wicker is very strong and durable and is available from the supply companies on the Cane & Basket Supplies Directory™

Paper fibre rush comes in a continuous pre-twisted strand coil, either by the 2-pound coil or 35-pound reel.

Little or no water is needed when weaving with paper fibre rush to soften or mellow the strands.

In fact, water is the enemy of paper rush and too much or soaking the paper can destroy it.

Knots or joins are made to connect one strand end to another and are covered in the gussets or pockets in the triangles and/or on the bottom of the chair seat, so they are not visible.

OAK, ASH, RATTAN REED, CANE & HICKORY BARK SPLINTS

These types of chair seats and backs are woven in two main designs, either herringbone twill or basketweave, but can also be woven in a variety of designs and patterns.

Splints or “splits” as they are sometimes called because they are split from the tree, are frequently seen woven on both the seats and backs of Southern porch rockers and settin’ chairs.

The splints used in this method need to be soaked in water until they are pliable enough to weave with, otherwise, they will crack and break and are very brittle when dry.

Flat splints or strips of rattan reed, oak, ash, or hickory bark which are woven around the rungs of post and rail chair frames.

This creates specific and different designs both on the top-side and underneath side of the seats and/or backs.

DANISH MODERN CORD or DANISH CANE SEATS

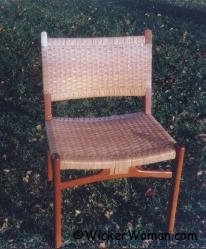

The craze and popularity of the Danish Modern furniture movement really took off here in the United States during the 1940s, 50s and 60s, but actually began in Denmark in the early 1920s.

Chairmakers such as Hans Wegner, Neils Møller, Borge Mogensen, Arne Jacobsen and others were designing smooth, sleek, organic and comfortable chairs, using quality woods (primarily teak), and craftsmanship.

The craft brown, 3-ply cord, which is made in Denmark, but does now come in an American version, is either in “laced” or “unlaced” form.

The laced version has a slightly bumpy or nubby look to it and the unlaced has a more smooth texture.

Chairmakers incorporated a 3-ply cord on their woven chair seats and would weave it around a series of L-shaped nails on the underside of the seat.

The seats were woven in a distinct and identifiable pattern, quickly becoming associated with the Danish Modern movement.

There are also several versions of the Danish Modern chairs, woven with wide binding cane, such as the one here in the picture.

SHAKER TAPE

Cotton Shaker Tape seat weaving originated with the Shaker religious sect back in the 18th Century here in the United States.

They wove the cotton strip tapes first and then wove the 1″, 7/8″ or 5/8″ wide strips on the seat frames of their chairs. These seats were clean, comfortable and relatively inexpensive to purchase when sold to retail consumers.

The material is available in a variety of colors and primarily two widths of 1″ and 5/8″ and can be woven on just about any post and rail (with seat rails or dowels) chair frames.

Shaker tape seats are particularly well suited to ladder back chair frames or any trapezoid (wider in the front than in the back) chair frame.

Pattern designs range anywhere from herringbone, checkerboard, diamond, and double-diamond to even more creative weaves!

Well, there you have it! Now you will be able to identify at least eight different woven chair seat patterns used on woven chair seats! Congratulations!

Keep in mind that this is only an introduction to the myriad of woven chair seat patterns, weaving materials and techniques used in producing chairs, so stay tuned for more!

Hope you enjoyed this FREE article on “How-to Identify Woven Chair Seat Patterns” and will help to support this information site by donating generously! Thank you!